When using tubular locks, businesses may encounter issues such as pin jumping, rusting, and disintegration, which can compromise performance, reliability, and security. To ensure long-term durability and safety, businesses prioritize manufacturers with advanced production capabilities and high-quality tubular lock solutions. So, how can you identify a reliable tubular lock manufacturer? As a specialist in precision locking solutions, Make Locks has been dedicated to the research, development, and production of tubular locks for over a decade. With outstanding craftsmanship and engineering expertise, Make Locks is your reliable partner.

1. Understanding the Basic Structure and Operation of Tubular Locks

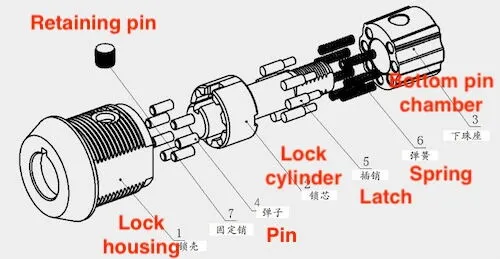

A tubular lock is a type of pin tumbler lock with a cylindrical pin mechanism, consisting of seven key components:

Lock housing: The outer structure that encases and secures the internal components.

Lock cylinder: The central component that determines key compatibility and ensures the lock’s security.

Bottom pin chamber: Holds the pins in position, ensuring proper alignment for reliable operation.

Pin: A critical component that interacts with the key to engage or disengage the locking mechanism.

Latch: Works with the top pin to control the locking and unlocking function of the mechanism.

Spring: Applies the necessary force to reset the lock cylinder after the key is removed.

Retaining pin: Stabilizes internal components and prevents unwanted movement of the lock cylinder.

The precise interaction of these components ensures the smooth and reliable operation of the locking mechanism. Therefore, when choosing a tubular lock manufacturer, it is essential to evaluate their precision engineering capabilities and the quality of their manufacturing processes.

2. Selecting High-Quality Materials to Enhance Lock Strength and Durability

Leading tubular lock manufacturers must implement stringent quality control measures over both materials and manufacturing processes to ensure structural integrity and long-term durability. Make Locks primarily manufactures its tubular locks using high-quality zinc alloys, ensuring superior resistance to impact and corrosion. Advanced multi-axis die-casting technology enhances the lock’s structural integrity, minimizing vulnerability to external forces.

3. Precision Machining for Consistent Lock Quality

Make Locks employs advanced precision machinery, including:

Multi-axis die-cast machines: Ensure high precision in lock housing and cylinder production.

CNC lathes: Improve dimensional accuracy and ensure seamless component integration.

Automatic key milling machines: Ensure precise key cutting, enhancing lock security.

Throughout production, we strictly control key parameters, including component dimensions, assembly tolerances, and coating thickness, to ensure precise component fitting. This enhances operational reliability and extends the lock’s service life.

4. Optimizing Key Components to Enhance Lock Security

To enhance the security performance of tubular locks, Make Locks has specially engineered key components, including lock cores, latches, and springs:

Anti-bounce pin mechanism: Reduces the risk of pin displacement, ensuring long-term lock stability.

Corrosion-resistant surface treatment: Employs bright chrome, bright nickel, and other plating processes to enhance corrosion resistance, ensuring reliable performance in harsh environments.

5. Rigorous Testing Standards to Ensure Product Quality

Before shipment, each product undergoes thorough testing for key performance criteria, including:

Durability test: Simulates prolonged usage conditions to validate the lock's durability.

Anti-bounce pin test: Assesses the effectiveness of the anti-jumping design, ensuring long-term stability.

Lock cylinder tail force test: Assesses the structural stability of the lock cylinder under force.

Key torque test: Measures the key's resistance to deformation under varying torque levels.

Salt spray test: Evaluates the lock's corrosion resistance to ensure functionality in high-humidity, high-salinity environments.

6. Conclusion

A tubular lock exemplifies precision manufacturing and rigorous quality control. Make Locks is dedicated to continuous improvement and prioritizing quality, providing safe and reliable locking solutions. For more information about Make Locks' tubular locks, please feel free to contact us. Our team is dedicated to providing expert consultation and exceptional service.

Español

Español 中文

中文