When choosing lockset, people are often worried about that locks are not durable or soon rust and oxidize on the surface. This problem can directly influence the materials and surface treatment. Now let's introduce different lock materials from different perspectives. From the perspective of the durability: 1. the best material should be stainless steel, which become more and more shining especially when used as the surface material. It has very good strength, strong corrosion resistance,...

General Knowledge of Door Locks

This technical article introduces some general knowledge of door locks, including its category, selection matters and install methods. Categories 1. Anti-theft lock. Exterior entry door is the divide of home and outdoor. It must have the function of insurance and security. The door is usually consisted of two: iron gate and door (usually a wood door). As for iron gate, it should be locked from both sides, which is called double-end lock. It should be noticed that the distance between the two doors...

Measures to Protect Door and Window Hardware from Damage

Reasons for hardware breakdown: Incorrect hardware accessories, which brings to poor quality; there is no metal plate at the fastening, which results in poor installation strength. General hardware damages are: insecure hardware fittings fixation, mobility, the damage of pulley and friction hinge, and opening and closing is not flexible. Measures to prevent the damage: The model, specification and performance of selected hardware accessories should comply with state current standards and...

Notes for Selecting Locks

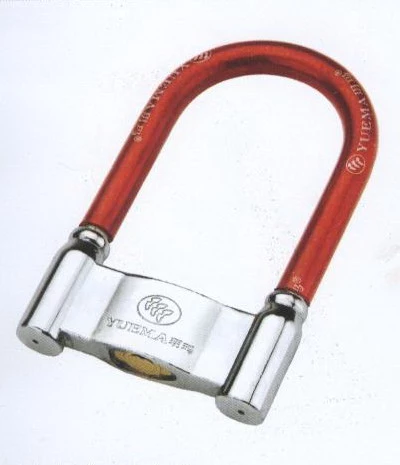

There are many classifications, complex hardware locks materials and processing technologies in the market and different standards or specifications, the following gives a simple instructions about how to choose the hardware locks. 1. Locks materials The lock material on the market can be basically divided into stainless steel, copper and zinc alloy. Stainless steel has high strength, strong corrosion resistance, non-discoloring, which is the best building materials; Copper is generally used, whose...

Considered Factors before Buying Locks

With the rapid development of pillar industries, such as house, car, high-grade office buildings and hotels etc., and national defense, public security, finance and other systems growing demand for high defensive locks products, high-grade locks have a optimistic market outlook. Lock itself is a decoration, and if the material or coating appears problem, it can lead to rust or coating color fall off. It is suggested to choose gold-plated copper or other coating adhesion. With the continuous improvement...

It Is Important to Maintain Locks

During normal application, if there is any dirt, you can use dry cloth to clear, but do not use chemicals such as detergent to scrub, which can damage the leakage protective film and cause fading. Don't use wet cloth to wipe the lock body and the handle, because some of the metal locks will rust; alloy material will wear off films of locks, so to lose beautiful effect. In use process, some of the zinc alloy and copper locks will have "spots" after a long time installed on the door,...

Locks Expiration Date

At the present market, the door lock is classified into class A and class B, super class B, etc. Consumers can identify its quality by billiard row number of locks. In general, rows cylinder locks are better than single one, and rows invisible lock is superior to the ordinary kind. The cost of B bolt is much higher than A, therefore, most of the lock brand products in the market are A lock. If the security door keys have one row of marbles, it may be A lock. If you feel it is not safe enough, you...

The Maintenance of Locks Appearance and Performance

This technical article introduces the maintenance methods for locks appearance and performance. The maintenance of locks appearance 1. During house decoration, please use plastic bags to seal lock handle, panels and other exposed parts, so as to avoid the lock parts surface treatment layer is covered with acidic or alkaline materials and gas erosion spots, and even delaminating phenomenon, which seriously affects the appearance quality of the locks. 2. During normal application, if there is any...

Locks Parts Processing Technic Analysis

This technical article analyzes the processing technic of locks components from four points. 1. The materials of locks parts such as lock case, lock catch and cylinder are most iron casting. Their surface is rough, so we can use grinding wheel to polish it. 2. Polishing cylinder circle uses rag wheel of flat shape. Because of its concave and convex surface, we use new polishing cloth. At present polishing cloth is used mainly for well-distributed polishing. Wipe grease on the wheel and two...

Locks Polishing Materials and Their Functions

This technical article introduces six materials used for locks polishing and their functions. Materials and their functions for polishing locks: 1. Secnidazole: in liquor, its function is passivation and polishing, which directly affect the speed and quality of polishing. When its concentration is too low, its reaction speed will be low too, the surface gloss is poor after polishing. While on the contrary, there will appear some pitting corrosion on the surface after polishing. 2. Phosphoric acid:...

Precautions for Locks Polishing

This technical article illustrates the precautions before and after polishing for locks set. 1. The workpiece must go through the drying processing before polishing, in order to avoid that solution is diluted by water and therefore affect its glossiness. 2. After polishing, the workpiece should be put in at room temperature, dry 400~500 g/l nitrate or in the 100~200 g/l Lattice inebriate solution in a few seconds to 10 seconds to remove the surface metal. Except for mechanical prime light and chemical...

The Maintenance Methods of Locks

Although lock is a small hardware accessory, which is consisting in door and window hardware, it plays a most important role in our daily life. Therefore it is crucial to maintain it. 1. When the door lock is not easy to be opened or closed, you can spray some lubricating oil on the lock bolt. 2. Some kind of plug cannot be added fabricating oil, such as dual bead lock. 3. The door crack should not be too large, which may make it easy to open or make noise. 4. When the lock is not so easy to be...

Español

Español 中文

中文